In Ireland there is a constant presence of wind and wind turbines of various sizes and capacities are widely used, but no wind mechanics are used yet. According to the standards, to obtain 1 kWh of electrical power from the generator, the shaft of the wind wheel itself must have 1.5 times more mechanical power, and some manufacturers make even 2-2.5 times more. I think this is a big disadvantage because of energy losses. It is necessary to make a wind mechanic, which will produce heat directly from the wind without an intermediary in the form of electricity.

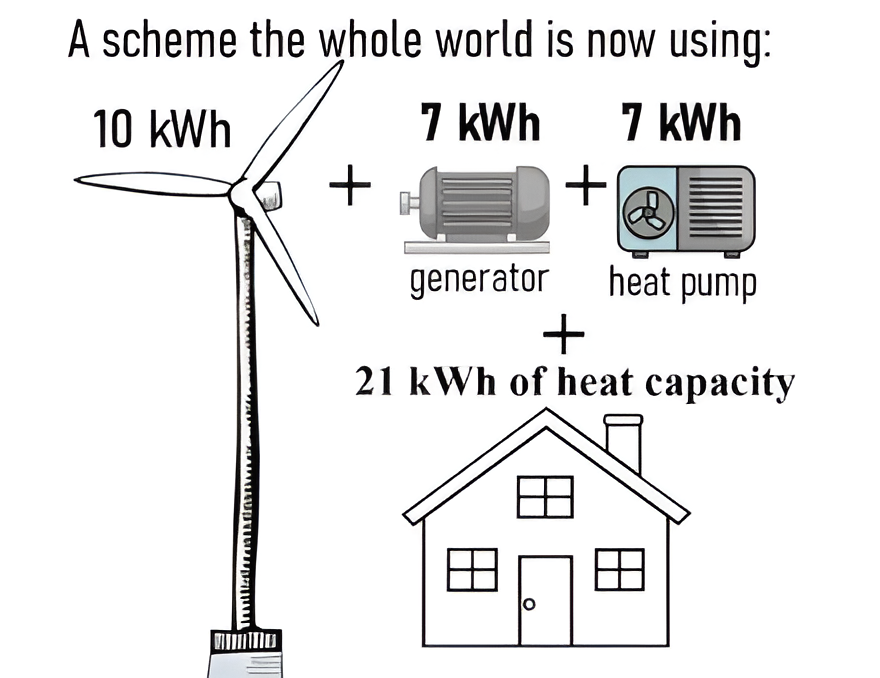

Old scheme

On the shaft of the wind wheel we have, for example, 10 kWh of mechanical energy, which is connected to a generator with a capacity of 7 kWh (observing an energy loss ratio of 1:1.5).With the help of the generator I, for example, plan to heat my house with a heat pump. Accordingly, in this case I will not be able to install more than 7 kWh of power on it. The heat pump, in turn, will only be able to transfer 21 kWh of thermal energy to the house (the average ratio of electrical to thermal energy transfer is 1:3).

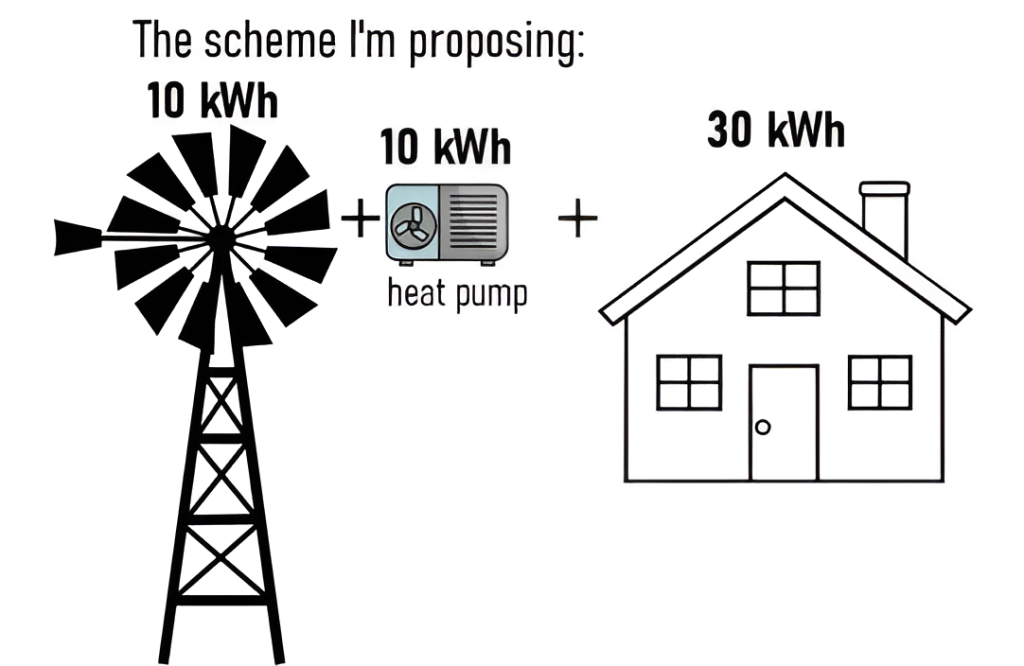

New scheme

We have the same 10 kWh of mechanical power on the wind wheel shaft, which is connected directly to a mechanical compressor or heat pump (as in a car). Thus, we get a mechanical heat pump with a capacity of 30 kWh (average electrical to heat transfer ratio of 1:3). As a result, we have a 42% more efficient system compared to the first option used. Plus, by removing a whole node from the design, in the form of a generator, we will increase the reliability of the entire system. The fewer the links, the stronger the chain. This is the best scheme at the moment.

Also, I can suggest other effective ways of transferring mechanical energy into thermal energy, for example, with the help of Foucault currents or with the help of direct mechanical braking.